C-EPS assembly and testing production line

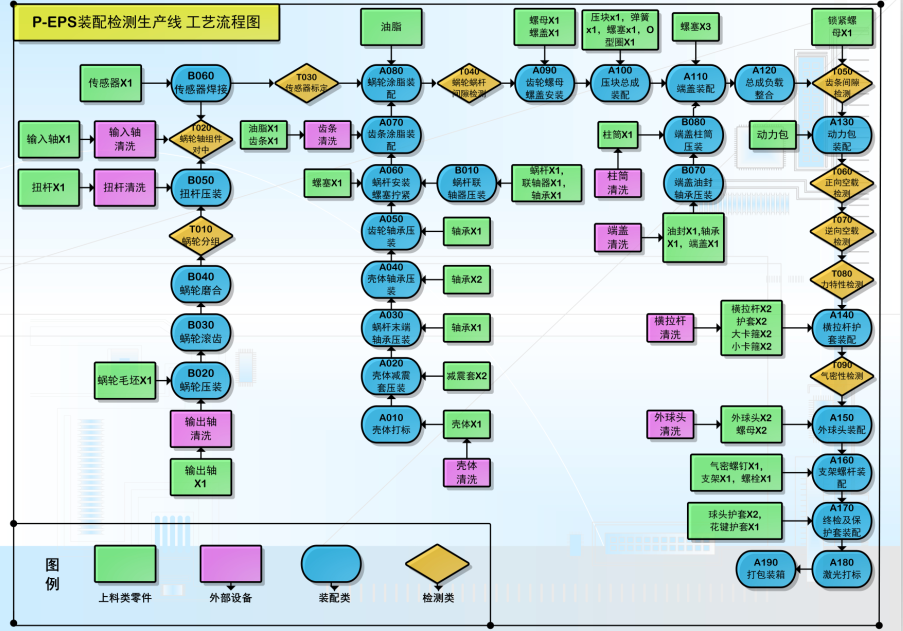

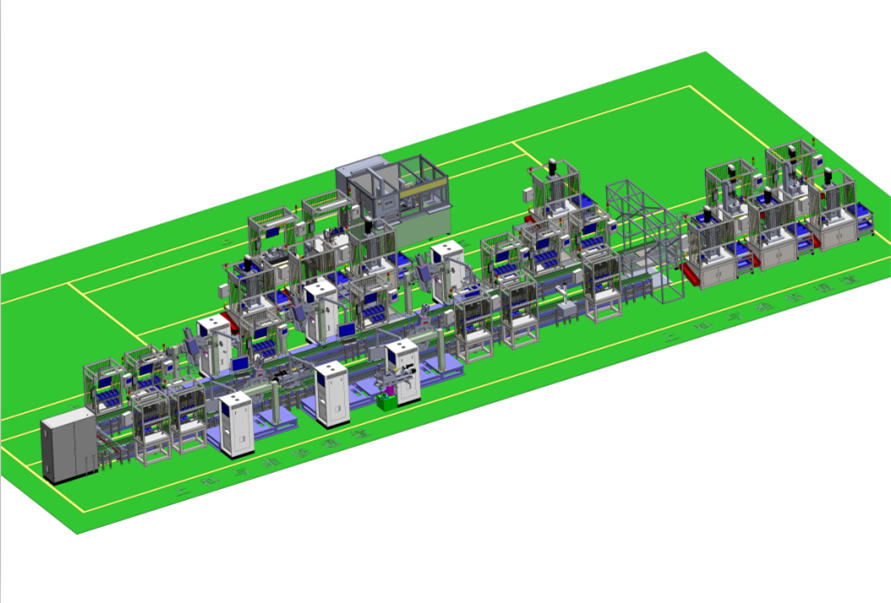

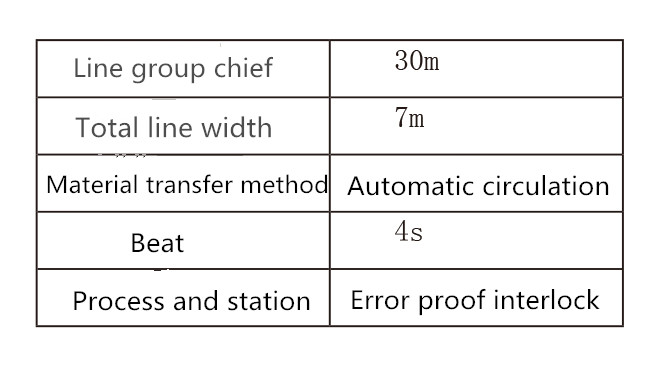

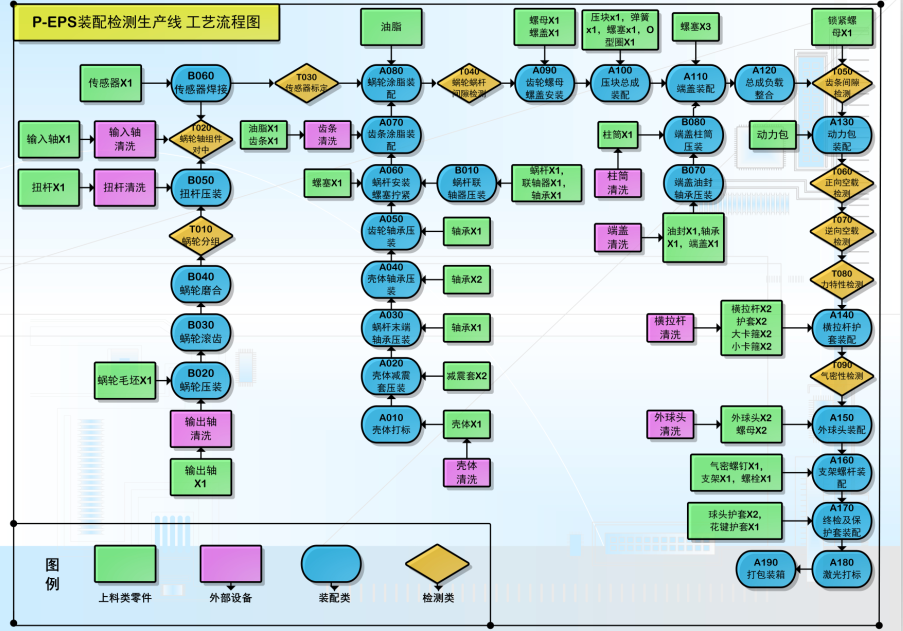

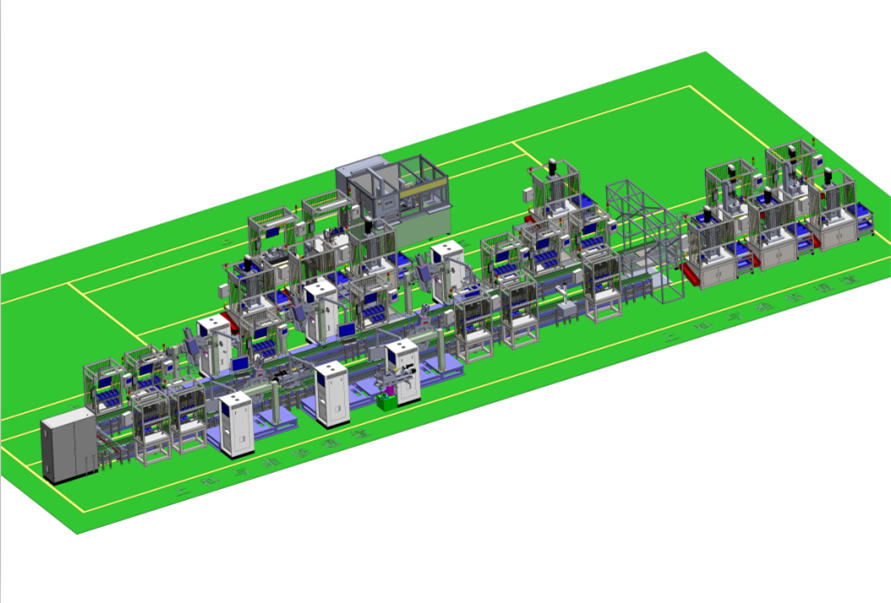

C-EPS automated assembly and testing line mainly include shell marking machine, pressing bearing and plug machine, pressing pin of shafting machine, fitting shaft and shell, shaft and worm gear machine, sensor welding and calibration machine, pressing worm, bearing and claw coupling machine, coating and assembling worm and shell machine, pressing the cover bearing, oil sealing machine, loading and grinding machine, ECU assembly machine, factory performance machine, final inspection marking and auxiliary logistics equipment machine.

The assembly line adopts automatic production management system, which can accomplish real-time monitoring, data collection and processing, state mark, and integrate with the operation control system. Assembly work table can realize components preloading, screwing up, press down, visual inspection and barcode identification. It can also realize the increasing force and position online detection function of by using mechanical and electrical leakage and error prevention technology. With the industrial control computer as the core, the comprehensive management can make statistics according to various conditions to generate reports, and retrieve all kinds of information of production records according to product serial number and other information. The report and retrieval function can be used for management and after-sale service separately from the production line.

Application and benefits

● The equipment is suitable for parts pressing and testing of various C-EPS products.

● Scientific process steps are organized to form a regular balance rhythm. The whole assembly line possess the function of error prevention, detection and monitoring to ensure assembly quality.

● It can test the brush motor and brushless motor. The hardware has a switchable interface, the software can be freely switched on the screen, and different products test can be selected by changing the message through the software.

● The equipment possess K and CAN line test functions

● The equipment is controlled by PLC and industrial computer. It adopts the advanced digital and analog electronic counting, high precision sensor technology, and fast data acquisition, real-time data processing technology. The system is high degree automated to simulate the actual working status of EPS and real-time testing every performance of EPS.